Our engineers are always working to design and build sustainable solutions for the plastics and powder coatings industries. Xtrutech’s latest developments focus on reducing waste during production and improving efficiency through recycling. After receiving our ISO 14001 certification we are even more focused on creating environmentally conscious equipment.

Fines recycling

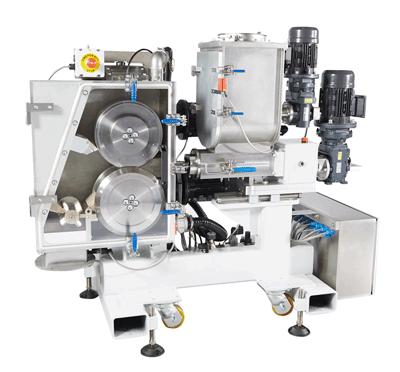

This month we released our latest Fines Recycling System, the XTS Compactor has been designed to drastically reduce waste during powder coating production.

Typically, between 2% and 10% of fines are produced during the milling process either in the bag house or 2nd cyclone. This means during a 5000kg batch which produces 3% fines, approximately 150kgs of raw material is lost.

Xtrutech’s XTS Compactor aims to combat waste by recycling fines and returning them to the mill as chips. Using this method, we can offer our customers a 99.5% product yield! Continue reading about our compactor here…

PET recycling equipment

Polyethylene terephthalate or PET plastic is one of the most common materials used for making everyday products such as plastic bottles, packaging, and clothing and manufacturers face increasing pressure to reduce, reuse and recycle their plastics…

Xtrutech can now provide a creative solution by recycling PET back into the production process. We have successfully demonstrated that Xtrutech can reprocess various PET and in particular PET fines.

As a result, we can offer our customers a closed loop of operation, so you can utilise quality materials in-house that would have been destined for landfill.

If you would like to learn more about our PET recycling equipment, contact our sales team via sales@xtrutech.com