From exploring our own XTS extruder range to innovations in the powder coating industry, the Xtrutech team have compiled some highly detailed articles this month, discussing trending industry topics such as “fines reprocessing”. Our sales manager for North America Daniel Johnson, provided some excellent insight into how many powder coating producers are losing valuable time and materials as a direct result of wasted fines. Detailing how Xtrutech have worked towards dramatically increasing fines efficiency for our customers to maximise their potential profit.

“In light of the anticipated changes, and the effects of the Coronavirus pandemic on the economy, the need for more environmentally compliant processes, operational cost savings, and improved productivity has never been bigger, this brings me to this year’s hottest topic: Fines Recycling…”

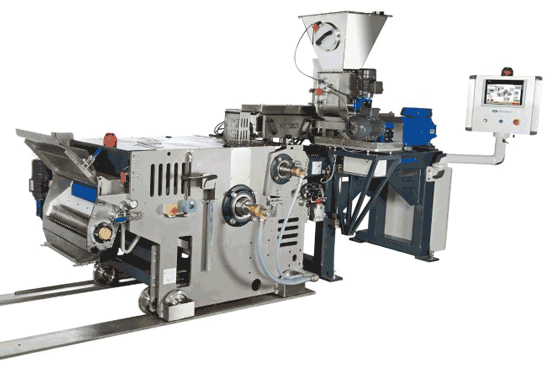

“Xtrutech has always been ahead of the curve when it comes to producing innovative and sustainable solutions in the powder coating market, and the release of the highly anticipated and affordable XTS35 Fines re-processing unit is no exception.”

“By utilizing a specialised screw profile and XTS side feeder, the XTS35 Fines re-processing unit allows re-processing of up to 100% of all fines (either from the mill’s baghouse or secondary Cyclone) and chips directly back into the mill in the same batch. With its affordable price tag, small real estate footprint, and expected throughputs of up to 220lbs per hour (100kg)*, it makes a great addition to any powder plant looking to increase efficiency and profits, whilst simultaneously decreasing their environmental impact.”