Xtrutech provides extrusion equipment, ancillaries, spare parts, and services for all biopolymer applications that require twin screw extrusion as part of the process.

Our goal is to partner with you from the research and design stages all the way through to production. Discuss how Xtrutech can support your project through our knowledge of processing diverse biodegradable materials.

What Are Biopolymer Materials?

Biopolymer materials are polymers derived from renewable natural sources, such as plants, animals, and microorganisms. Unlike traditional synthetic polymers, which are made from petroleum-based resources, biopolymer materials are biodegradable and non-toxic, offering a more sustainable alternative. These materials can break down naturally in the environment, reducing their impact on ecosystems and helping mitigate plastic pollution. Common examples include polylactic acid (PLA) from corn starch and polyhydroxyalkanoates (PHA) produced by bacteria. Biopolymer materials are used in a wide range of industries, from packaging to medical devices, offering both functionality and environmental benefits.

- Biodegradable Polymer & Compostable Applications

Xtrutech specialise in complete extruder lines that are compatible with various water-soluble, water-insoluble, and compostable biopolymer materials, including:

- PVOH

- PLA

- PVA

- Cellulose

- Chitin

- Seaweed

- Starch-based biopolymer

Our team has secured successful results across both production and lab-sized equipment.

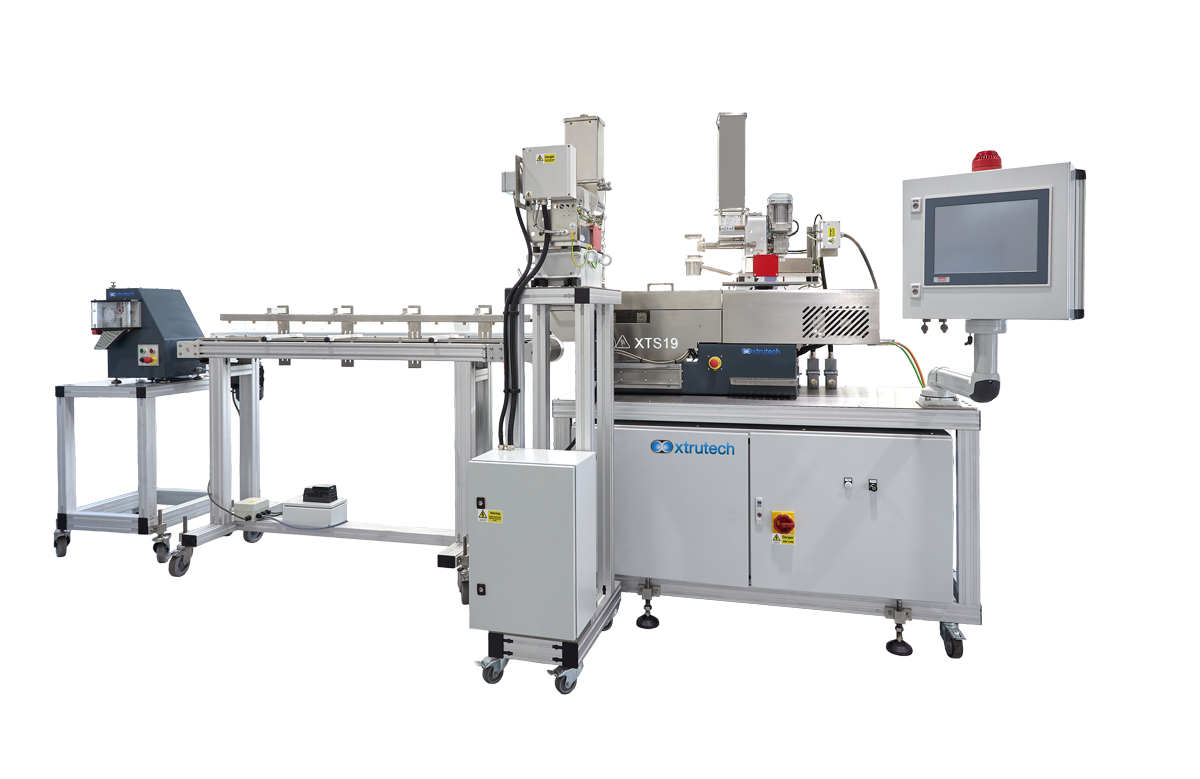

- Biodegradable Polymer Lines

Xtrutech complete production lines come with a range of up and downstream ancillaries to complement your material and process:

- High speed mixers for quality pre blend of formulation

- Volumetric & Gravimetric feeding systems

- Additional Volumetric & Gravimetric side feeding systems

- Liquid injection pumps

- Vacuum degassing

- Face cut pelletiser / Strand cut pelletiser

- Water bath or Cooling conveyors for compostable / water soluble materials

- Chill roll cooling

- Film calendar winder units

- Monofilament winder units (3D Filament)

- Granulators

- Biodegradable Process Trials

At the Xtrutech Innovation Centre, our expert engineers can support trials which give you the chance to run biopolymer material. This allows our team to support optimisation of your operations, prevent common processing issues, and review performance and product compatibility on our machines.

In addition to our design and manufacturing services, we supply an extensive range of OEM components and spare parts to serve you with comprehensive solutions.

Applications of Biopolymer Materials

Biopolymer materials are gaining popularity in various industries due to their eco-friendly characteristics and versatility. In the packaging sector, they are used to create compostable containers, films, and bags, helping to reduce plastic waste. In the medical field, biopolymers are used to manufacture sutures, drug delivery systems, and tissue engineering scaffolds, offering biocompatibility and biodegradability. Biopolymer materials are also found in consumer goods like biodegradable cutlery, clothing, and agricultural films, providing a sustainable alternative to traditional plastic products. These materials allow industries to reduce their environmental footprint while maintaining product quality and performance.

The Advantages of Using Biodegradable Polymers

Using biopolymer materials offers several environmental and practical advantages. First and foremost, they are biodegradable, meaning they naturally break down over time, reducing the long-term environmental impact of plastic waste. Unlike conventional plastics that can persist in landfills for hundreds of years, biopolymers decompose quickly, leaving behind fewer harmful residues. Biopolymer materials are also often derived from renewable resources, contributing to a more sustainable production cycle. By choosing biodegradable polymers, businesses can align with eco-conscious consumers, enhance their sustainability efforts, and reduce their reliance on fossil-based plastics.

Sustainable Solutions with Xtrutech

By utilising renewable feedstocks such as plant-based polymers, twin-screw extrusion reduces reliance on fossil fuels and minimises environmental impact. The team at Xtrutech are here to help sustainability efforts with reliable, high performance equipment.

Xtrutech are committed to quality and environmental stewardship as we maintain multiple ISO certifications and are proud to be accredited with an EcoVadis Sustainability Award. Contact Us to learn more or request a quote.