XTS Side Feeder

Developed by Xtrutech to tackle the problem of aeration and bridging in the feed throat, Side Feeding effectively stabilizes the Torque allowing the extruder to be pushed harder for higher outputs.

Clean-in-Place System

The XTS automated Clean-In-Place system removes material from the interior surface of the hopper, without any need for disassembly and minimal operator intervention. This allows for the feeder to be cleaned in under 6 minutes.

Auto-Purge-System

This feature is customizable to your formula, Auto-Purge has a range of sequences based on your available preparation time and materials used in the process.

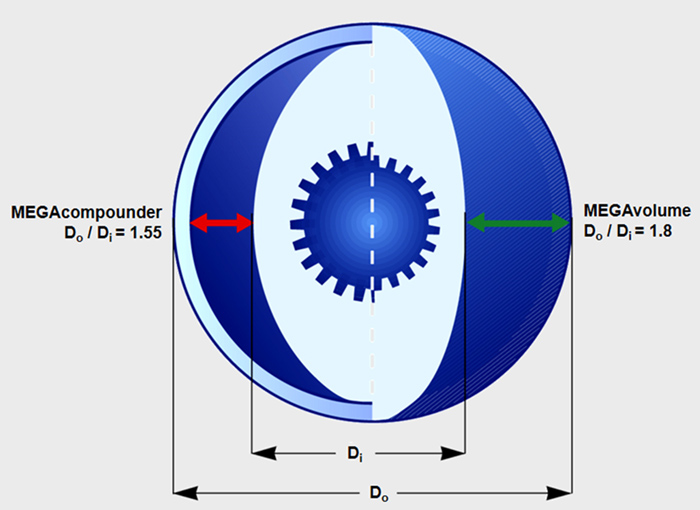

High Free Volume Geometry

The XTS range has the optimum high-volume geometry of D/d 1.8 for powder coating processing. Coupled with a high speed and high torque drive system and a 24L/D clamshell barrel, we have created the ultimate machine for processing powder coatings in the most efficient and economical way.

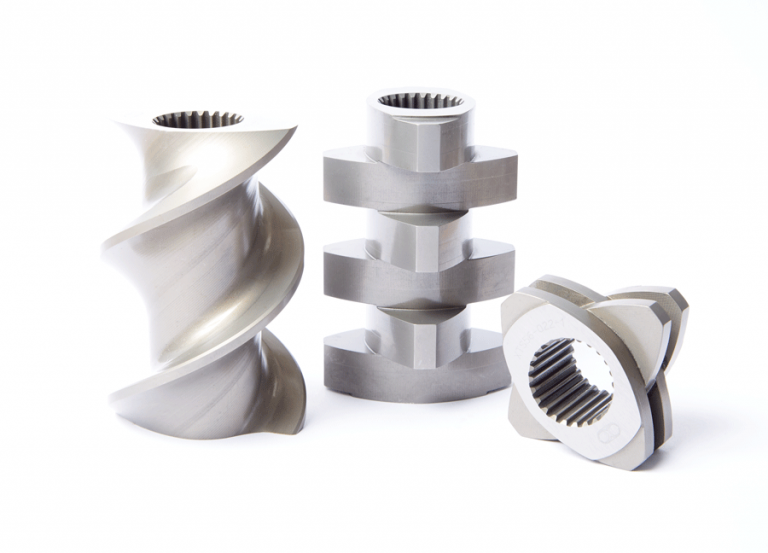

Wear-Resistant Materials

Xtrutech have designed a range of screw elements, barrels, and liners in extra-high wear resistant material for Powder Coatings production that offer optimum performance against cost.

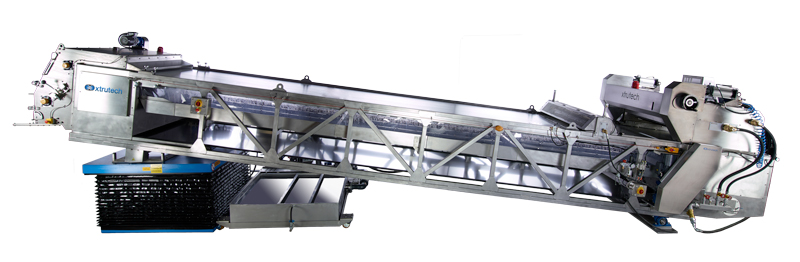

Seamless Integration

Complete, seamless, integrated powder coatings lines. Which include an XTS Twin Screw Extruder, Cooling Conveyor or Compact Drum Cooler and choice of feeder.

To learn more about XTS Extruders visit: https://www.xtrutech.com/twin-screw-extruders/