All Twin-Screw Extruders face the same two limitations, their installed motor power (often referred to as torque) and their volumetric capacity or intake.

The capacity or intake to any extruder is influenced by:

- bulk density

- changes in bulk density during feeding

- surface friction of the powder

- material flow ability

- aeration

The intake is affected by the bulk density of the premix, the higher the bulk density, the higher the throughput or kgs/hr. For example, powder coating fines have a typical bulk density of 0.2 or lower making them particularly difficult to feed.

When feeding materials into an extruder it is essential to minimise aeration wherever possible. This is because air circulates the screws and takes up space within the extruder. This creates unstable torque as the air finds the easiest route out of the extruder which is usually the feed port. It is this unstable torque that creates stress and potential damage to the shafts and gearbox. This can be compared to the effects of driving a car in a constant stop/start motion. It results in unnecessary wear that consequently impacts the gearbox, shafts, screws, torque coupling and to some extent the product being extruded.

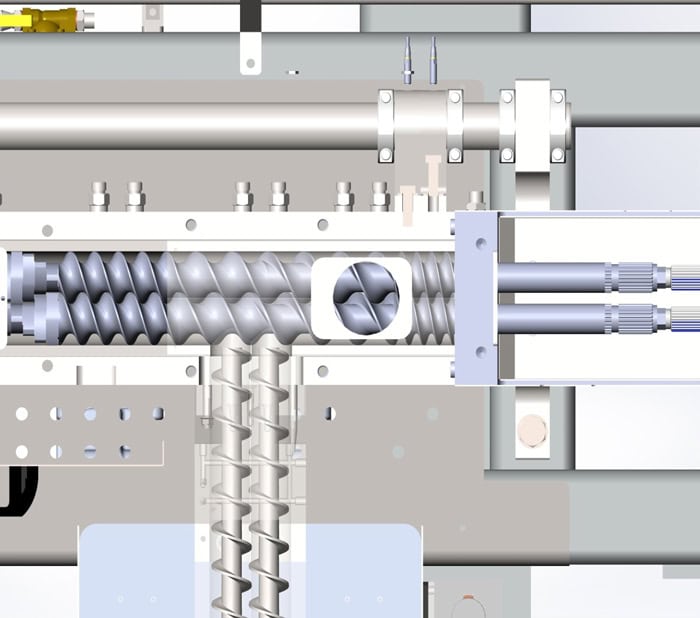

Top Feeding

Due to the nature of top feeding, as the premix drops from the feeder it is exposed to aeration, which is most common in low bulk density formulations as they are typically more difficult to feed. One way to combat aeration is to reduce the height of the feeder, which reduces the opportunity for air to enter the premix and encourages higher outputs.To counteract these issues in XTS feeders, Xtrutech extruders have large rectangular feed ports and low positioned feeders. When combined with Xtra-Volume (XV) screw elements we have found that the intake of materials is greatly improved.

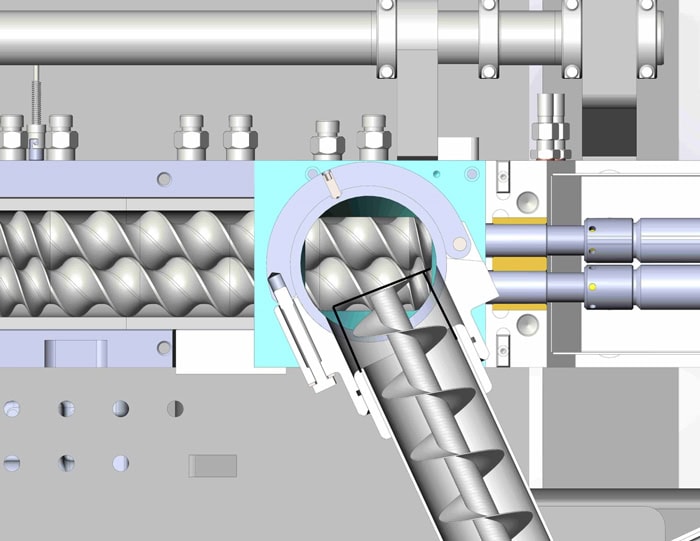

Side Feeding

However, the highest and most efficient outputs can be achieved using the XTS Side Feeding option. The side feeder addresses the problem of aeration in two ways: Firstly, the feeder is level with the side port and links directly to the XV feed screws, reducing the chance of air entering along with the premix. Secondly, any entrapped air is released via ‘back venting’ through the top feed port. This promotes stable torque and up to 30% higher feed rates than top feed options.

Therefore, side feeding is ideal for processing low bulk density formulations and darker colours, which also enables fines recycling. As a result, Xtrutech have been working on various ways to recycle fines, such as our XTS35 Fines Re-Processing Unit. Click here to learn more.

Summary

Side Feeding will maximise the volumetric capacity of your extruder so it will run at an increased kgs/hr. However, Side Feeding can be more beneficial for certain formulations e.g. Low bulk density and darker colours, but has no negative effects for general powder coating formulations.

In comparison, Top Feeding promotes aeration and unstable torque within the extruder, which will result in lower outputs and reduced service life of major extruder components.

Xtrutech offers both top and side feeding options depending on our customers preference. This includes our latest development, the clean-in-place (CIP) feeder. Which has been developed to further reduce cleaning times for our customers by automating the cleaning process.

You can learn more about which feeding options are right for your extruder by contacting sales@xtrutech.com or to learn more about the CIP feeder visit https://www.xtrutech.com/clean-in-place-feeder/