Twin-screw extruders are faced with two limitations, motor power and volumetric capacity. That capacity is influenced by bulk density, surface friction of the powder, material flow ability, and aeration.

Aeration Reduction

In order to maximise feeding volume it is essential to minimise aeration, which takes place when air enters the extruder with the premix. This takes up additional space in the extruder and when air tries to escape through the feed port against the premix, it causes unstable torque. Unstable torque will lead to the extruder tripping out when trying to run at higher capacities.

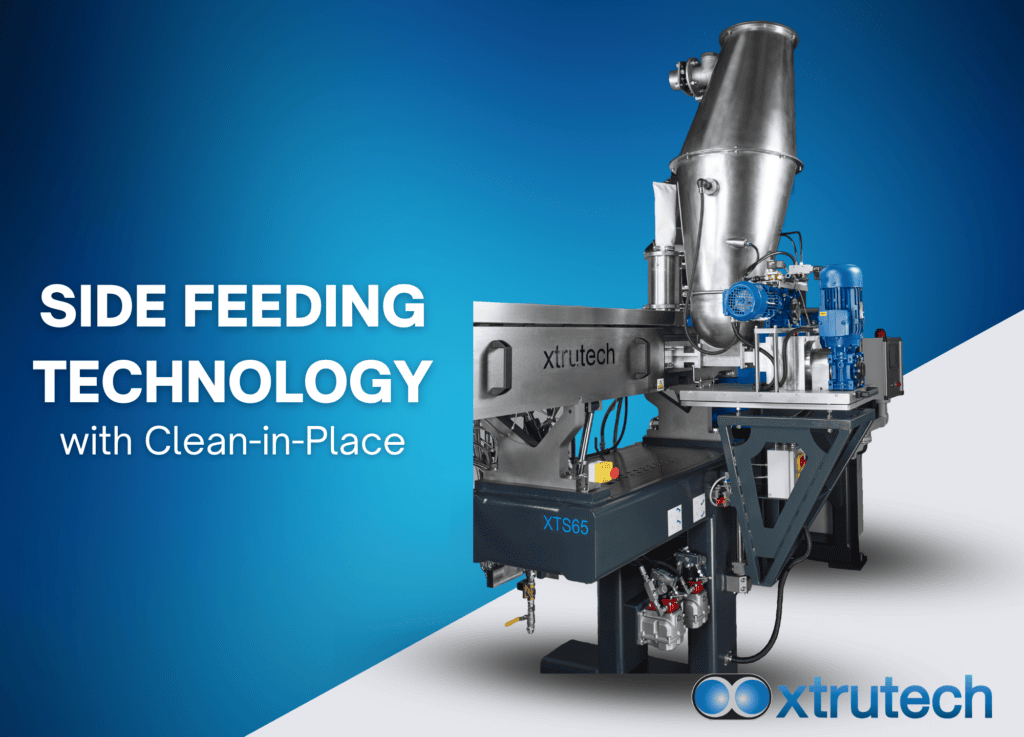

Side feeding addresses this by being directly connected to the feed screws at the side port to reduce the chance of air entering the extruder. Any additional air can be released through the back vent. This ensures stable torque and can lead to up to 30% higher feed rates depending on bulk density and formulation, whilst providing the most efficient outputs.

Clean-in-Place

Xtrutech also have an innovative Clean-in-Place, automated feeding and hopper cleaning system. The system uses compressed air and resin chips to create a vortex within the hopper to purge and clean the extruder in as little as 10 minutes. That is without the need for disassembly which further reduces downtime and increases valuable production time.

Speak to our expert team about side feeding and clean in place solutions today!