Types of wear

- Corrosive

- Adhesive

- Abrasive

Corrosive wear

Occurs because of a chemical reaction between the processing materials and the metal of the screw element and/or barrel. The corrosion will make the surface of the metal appear dimpled or pitted. This is not common within Powder Coatings but may be an issue for extruders in other applications. Although, if condensation is present on the internal surfaces of chilled barrel sections, this can become an issue for Powder Coating Producers. To protect our customers, all XTS spares are manufactured from quality steels that prioritise performance against cost.

Adhesive wear

This happens when metals rub together, it can manifest in several different ways depending on the cause. For example, if screw shafts are forced against the barrel, the outer diameter of the screw flights start to flatten. This also causes score marks on the barrel wall. If the screws are ‘deflecting’ and contacting each other, the wear pattern appears as scratches on the tips, flanks, and roots of the screw flights.

This is the result of insufficient support of the screws & shafts within the barrel. The screws within a Twin Screw Extruder are rigidly fixed at the gearbox end, the shafts are then supported by the molten resin that runs through the barrel during production. When screws are left to rotate (particularly at high speeds) in between production runs adhesive wear can occur.

To prevent unnecessary wear within our XTS machines we have automatic features in place for a controlled shutdown. If production stops and the torque drops to below 30%, the feeders will be shut off and the machine will slow down to an idling pace of 100rpm.

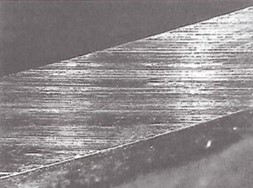

Abrasive wear

This is perhaps the most common type of wear in Twin Screw Extruders, it results in the erosion of both machined screw and barrel components. The sharp machined corners of screw and kneading elements appear rounded, smooth, and occasionally polished when subject to abrasion.

The level of abrasion depends on the following factors:

- Materials of construction for the barrel & screws

- Screw speed & throughput

- The formulation being processed.

This type of wear is dependent on the amount of material being produced rather than the time the extruder has been in operation. It is difficult to predict wear of this nature unless the abrasive characteristics of a particular production mix/formulation are known from experience.

When does a part need replacing?

As a rule, parts need replacing when a reduction in output and/or quality can be observed. By checking inside of the extruder barrel on a monthly basis, wear can be assessed in the early stages and replacement parts can be ordered before any additional damage is caused.

XTS owners can easily preform this as a method of best practice, the clamshell barrel included in all our extruders provides quick and easy access to the screws & shafts. We can also supply wear gauges for all XTS extruders to make the process even simpler. For extruder owners with closed or fixed barrels such as those from Coperion, we can offer alternative methods of wear measurement such as micrometer gauges & cameras to measure wear inside the barrel.

Guidelines for XTS Extruders

➢ Screw Elements – approx. 5% off the starting diameter over ¾ of the length of the part

➢ Barrel Liners– approx. 5% increase in the starting diameter over a length of 1D

For more information contact a member of our team via sales@xtrutech.com.