Powder coating is one of the most effective and commonly used finishing processes within the manufacturing industry. It is often chosen for applications such as automobile and household appliance manufacture, construction parts and bicycle frames to name just a few. When comparing powder coating properties to conventional paint, Its durability, cost-effectiveness, and aesthetic qualities make it an excellent choice for improving product longevity, style, and costs. As Xtrutech’s primary industry, we continually advance the capabilities of powder coating for both laboratory and production purposes.

- Powder Coating Key Features

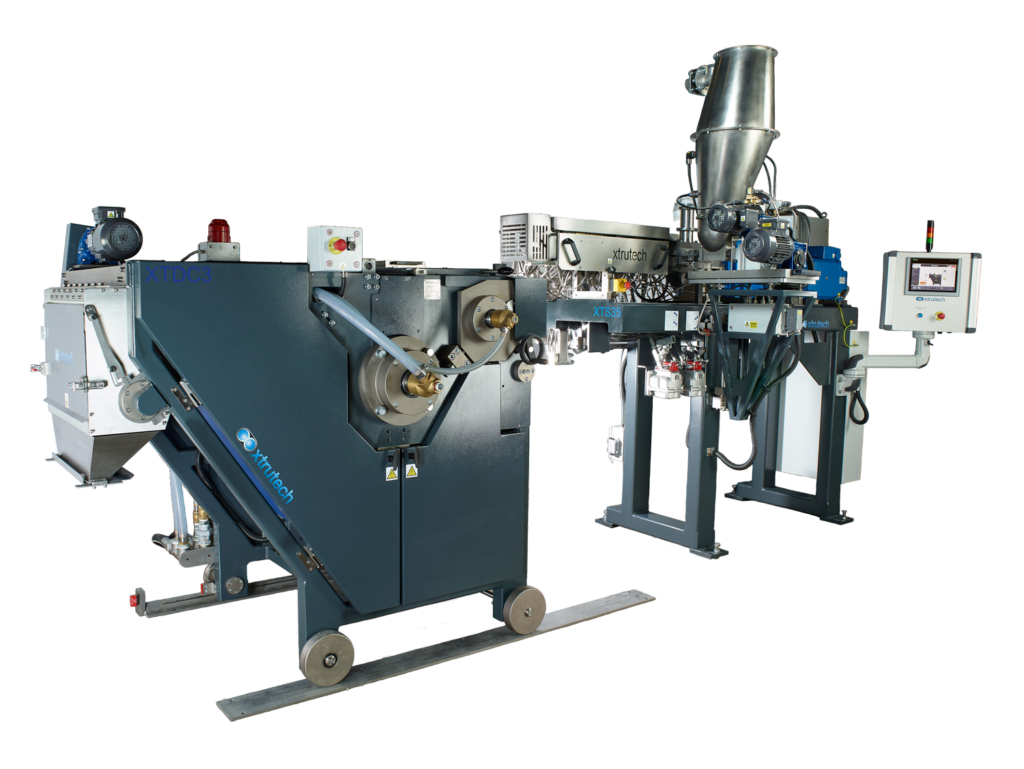

Xtrutech support an extensive range of powder coating services and finishing processes. We are a full in-house provider of powder coating extrusion equipment and technical support services.

In addition to our XTS twin screw extruders and complete powder coating lines, we provide a comprehensive range of equipment, including:

- Top feeders and Side feeders with Clean in Place (CIP) systems

- Drum coolers and Cooling conveyors

- Fines processors and Compactors

- Ancillaries

- XTS and OEM spare parts including

We support powder coating processes for laboratory and production environments, emphasising both mass efficiency and ISO quality standards. These efforts have made Xtrutech the only OEM provider of complete coating solutions, including maintenance and process optimisation.

Xtrutech Support Services

Xtrutech provide each customer a dedicated Regional Manager who who works with them to determine the optimal powder coating equipment and processes. This can include free process trials using your formulation in our innovation centre. Contact us to learn more or request a quote.