Xtrutech specialises in innovative solutions for the powder coating industry, particularly through its line of powder coating twin screw extruders. These machines are made to deliver superior performance in both laboratory and production settings, making them ideal for small-batch testing, formulation trials, and large-scale production.

Xtrutech’s Twin Screw Extruder Range

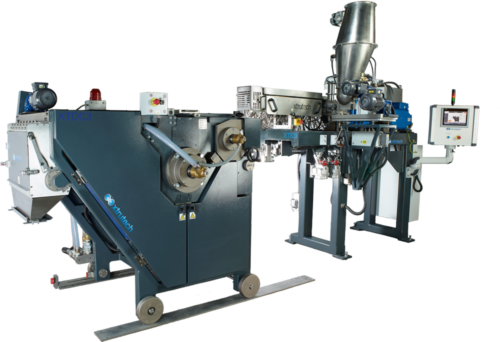

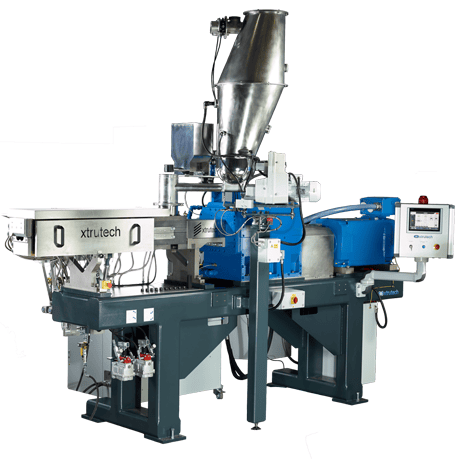

Xtrutech offers a diverse range of twin screw extruders designed to optimise powder coating processes. Key models include the XTS24, XTS35, and XTS56, each tailored for specific applications and requirements.

The XTS24 Twin Screw Extruder is a lab twin screw extruder ideal for laboratory applications and low-scale production, particularly optimised as a powder coating twin screw extruder. With high free volume and individually controlled heating zones, it ensures precise processing. Barrels are available in standard lengths of 24D and increments up to 54L/D for versatile applications.

The XTS35 Twin Screw Extruder is a versatile 35mm model ideal for both laboratory and low-scale production. With high free volume and individually controlled heating zones, it ensures optimal temperature management for precise formulations. It seamlessly pairs with an XTS cooling system for efficient operation.

For full-scale production, the XTS56 Twin Screw Extruder offers a robust solution designed for high-output applications. The XTS56 efficiently processes large volumes, making it ideal for optimising powder coating production.

We also provide a range of twin screw extruder spare parts, including screw elements and barrels. Many customers mix and match extruders from various manufacturers. Buying spare parts from us is often more cost-effective and faster than sourcing from the OEM, ensuring your operations remain efficient.

Key Features of Xtrutech Twin Screw Extruders

Xtrutech’s twin screw extruders are equipped with advanced features that enhance their functionality and reliability. The extruder screw elements are segmented to allow precise control over the material processing. The segmented design includes Xtra Volume screw elements that optimize the feeding of fines and low bulk density formulations, crucial for efficient powder coating operations.

The clamshell barrel design of these extruders provides easy access to the screws and shafts, facilitating maintenance and adjustments. The use of insert liners, which can be made from wear-resistant materials, ensures longevity and cost-effectiveness, as they are simple to replace when necessary.

Each model is designed to integrate seamlessly with Xtrutech’s cooling systems, such as the XTDC Drum Cooler and XTCC Cooling Conveyor. These cooling solutions are essential for maintaining optimal processing temperatures, particularly in high-output settings.

Applications of Xtrutech’s Powder Coating Twin Screw Extruders

Powder coating is widely used across various industries, including automotive, household appliances, and construction. The durability and aesthetic qualities of powder coating make it an attractive finishing option for manufacturers. Xtrutech’s twin screw extruders are engineered to support these applications, ensuring high efficiency and quality.

The versatility of these machines allows them to be used not only in laboratory environments for R&D but also in large-scale production lines. By offering tailored solutions for both settings, Xtrutech ensures that customers can achieve the desired outcomes in their powder coating processes.

Optimise Your Powder Coating Production with Xtrutech

Choosing the right equipment is essential for optimising powder coating production. Xtrutech’s range of powder coating twin screw extruders offers advanced engineering and customisable features that cater to both lab and production needs. By focusing on high efficiency and superior performance, Xtrutech remains a leader in providing innovative solutions for the powder coating industry.

Ready to enhance your powder coating processes? Contact us today to learn more about our twin screw extruders and how they can benefit your operations!