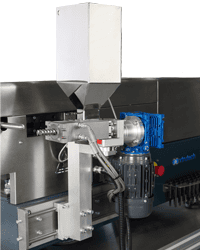

Xtrutech manufacture a range of Twin Screw Side Feeders suitable to fit various sizes of extruder for laboratory and production use. The range of high powered feeders feature a variety of feeding options for both powder premixes and liquid formulations.

Xtrutech’s Side Feeders offer reliability, high outputs with stable torque and running conditions. The torque is stabilised due to the consistency of the feed rate, so higher outputs can be achieved on most formulations. This is particularly effective when processing low bulk density formulations or recycling fines.

Xtrutech’s production side feeders – TSSF-30 and above can be fitted with an automatic assisted CIP (Clean in Place) Hopper, which dramatically reduces the time taken to clean the hopper between colour changes. See more information by clicking on the CIP tab.