A Demonstration of an XTS Cooling Conveyor & Scissor Lift

XTS Compactor: A Fines Recycling System for Powder Coatings

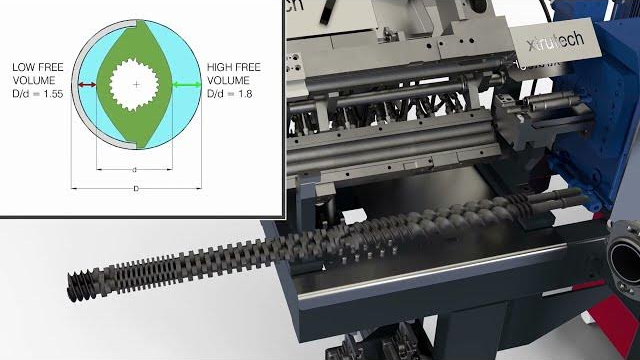

How to assemble screw elements for a Twin Screw Extruder with an Xtrutech service engineer

In this video we will show you how to assemble a set of screw elements for a twin screw extruder. This will be demonstrated using elements from our XTS44 Twin Screw Extruder for powder coating production. In this training exercise our service engineer will guide you through some of the most common mistakes & best practices.

XTS19 Twin Screw Extruder Laboratory Line | Xtrutech | XTS Range

In this video we are demonstrating the XTS19 Twin Screw Extruder line, which includes a top feeder, water bath, and pelletiser.

Xtrutech design and manufacture laboratory scale Twin Screw Extruders that are ideal for plastic extrusion. We also produce the XTS range of ancillaries which pair seamlessly with all XTS extruders. Our aim is to create highly efficient Extruder Lines that are both productive and simple to maintain.

High Speed Mixers | Xtrutech | XTS range

In this video we discuss the capabilities of the M3 & M5 models which feature a change-bowl design, making them ideal for use in laboratory and R&D applications. We also discuss the M10 model which has a larger fixed-bowl design, making it more appropriate for use in a production setting or where an increased capacity is required.