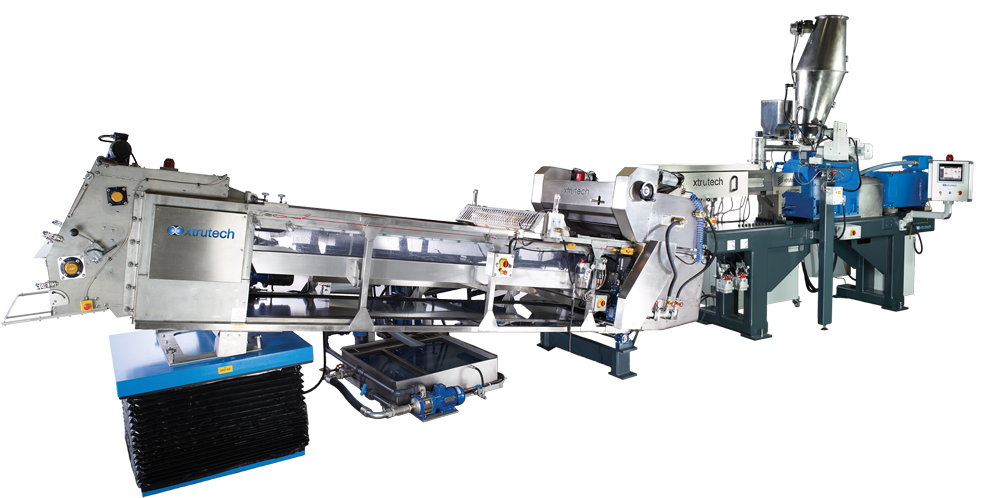

The XTS44 is the first full-scale production Twin Screw Extruders in the XTS range, designed with high free volume clamshell geometry combined with a robust and reliable high-torque drive. This makes XTS twin screw extruders ideal for high-output and efficient powder coating production.

Barrels come in standard length of 24D and in 6D increments up to 54L/D for more complex applications.

All XTS Twin Screw Extruders have been designed to pair seamlessly with an XTS cooling system. The XTS44 has the option of either an XTDC Drum Cooler or XTCC Cooling Conveyor. The XTDC4 Drum Cooler offers compact and efficient cooling. Whereas, the XTCC 1m X 5m cooling conveyor features an all-stainless-steel design to support optimum cooling efficiency, and to protect the conveyor from corrosion and contamination.

- Features

- High free volume coupled with high power enhances flexibility in speed, residence time and output.

- Clamshell barrel which allows essential access to the screws and shafts.

- Individually controlled heating zones (3D or 6D) for more control over your process.

- A split stuffing box gives quick access to shafts during removal and refitting.

- Oil impregnated brass split bushes to stop the material from flowing backwards towards your gearbox.

- Segmented Xtra Volume Screw Elements to optimise the feeding of fines and low bulk density formulations.

- An industry proven gearbox from PIV to ensure reliability of high torque transmission.

- Insert liners which are cost effective to replace and can be made from wear resistant materials.

- Torque limiter coupling to protect the gearbox, shafts, and screws.

- Super robust backing blocks with excellent control over heating and cooling.

- AC Water-cooled motor offers highly efficient torque transmission and low maintenance.

- PLC controlled with operator friendly HMI screens.

- Data

- Max Output: 800 kg/h

- Average Output: 500kg/h

- Max Torque: 390Nm per shaft

- Motor Power: 73.5/98 kw

- Standard Operating Temp: 250°C (450°C available on request)

- Screw Speed: 900rpm with options for 1200rpm

- Dimensions

- Barrel length: 24 – 54 L/D

- Length: 3240mm (Dependent on barrel length)

- Height: Varies dependent on individual requirements

- Width: 1650m

- Build a Seamlessly integrated Production Line